Polyaspartic Floors & Epoxy Floor Coating Services

Free Estimates

Over 20 Years of Experience

Locally Owned Business

Hours:

We Have the Options You Need for All Situations!

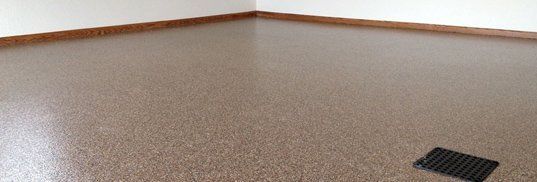

The polyaspartic floor sealing technology used by the professionals at Fargo Garage Doors & Floors is great to protect your garage floor and make it look unique. Our huge selection of chip flake and quartz aggregate colors can suit any style or aesthetic.

Because of the non-slip and stain resistant nature of the coating, it's great for commercial use as well. Businesses ranging from hospitals and restaurants to even dog kennels can benefit from a polyaspartic sealed floor.

Our Unbeatable Coating Process

First we diamond grind the top layer of the concrete and vacuum to insure a smooth and clean surface. What follows is 3 layers of polyaspartic chemicals and one final layer of custom selected chip flake or quartz. After 24 hours, you have a usable, unique and beautiful floor that will last a long time!

Experienced Experts With Polyaspartic Advantage

Fargo Garage Doors & Floors is at the cutting edge of floor sealing technology. We were the 8th team to be certified in polyaspartic coating. We’ve been working with the material longer than our competitors. Trust us and the strength of polyaspartic coating!

Call us today.

Consider How You Come and Go

Most people don't use their front doors to enter their house, instead they use their garage doors. They use the same way while leaving the house. Likewise, your garage is the first part of your home many of your guests will see. Create a lasting impression on them with Fargo Garage Floors & Doors!

Our Coating Process

The first step in the process is the diamond grinding. This step is critical in creating a durable floor. Diamond grinding takes off the top layer of the concrete, which opens the pores. This will create a flat, smooth surface by reducing high spots and lead to consistent application of the coating.

During this process, all cracks and decaying concrete are filled. Our crack filler absorbs into the walls of the cracks to prevent the moisture pressure that can delaminate your floor. Our grinders have an attached vacuum which produces a virtually dust free environment.

After the grinding is completed, the floor is vacuumed to remove any remaining particles and provide maximum adhesion & wetting of the Epoxy to the floor. The standard garage floor consists of 3 layers: 2 Thick chemical layers and 1 layer of solid chips.

The first layer is a tinted epoxy coat that will wet and seal the floor.

While this coat is wet, your vinyl chip color (2nd layer) is broadcast into the layer until it is 100% covered. Approximately 12 hour later, the chip coat will be dry. Any excess chips will be removed and the floor is scraped to produce a flat surface.

The 3rd layer is a thick, clear, high gloss polyaspartic. Anti-slip segments can be added to this layer if desired. After 4 hours, you are able to start walking on the floor. After 24 hours, the floor is ready to be driven on again.

Fargo Garage Floors Commercial Uses

We can provide flooring for many different areas such as cafeterias, churches, dog kennels, hospitals, restaurant kitchens, hotel pool areas, bathrooms, locker rooms, and much more.

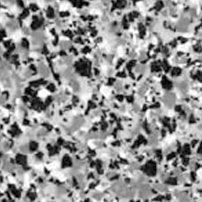

Commercial flooring is different than residential because it uses quartz granules instead of vinyl chips. The advantage of quartz is that it's more durable and more slip resistant as there's an additional layer of polyaspartic for commercial floors and epoxy flooring.

Polyaspartic coatings can also be applied vertically over cove molding. This creates a waterproof barrier for the wall. Quartz flooring can also be used both indoors and outdoors.

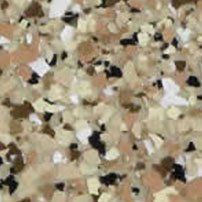

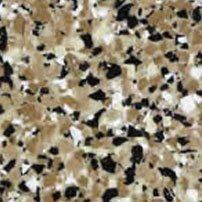

Chip Flake Color Varieties

Advantages of Polyaspartic Floors

- The polyaspartic advantage

- UV stable

- 4x stronger than epoxy coatings

- Oil, salt, and chemical resistant

- Slip resistant

We use polyaspartic flooring material because it simply gives you a stunning and incredibly durable finish. The result is an aesthetically pleasing concrete floor finish. In some instances, the entire flooring system can be installed in just one day allowing for heavy traffic within a matter of hours.

Polyaspartics are perfect for the harsh climate changes of Minnesota and North Dakota as the material is applicable in below freezing temperatures and is chemical (salt) resistant.

Common Uses of Polyaspartic Flooring Systems Include

- Hospitals

- Locker rooms

- Restrooms

- Commercial / retail

- Walkways

- Food preparation

- Patios

- Garages

- Showrooms

- Restaurants

Superior Polyaspartic Floor Coatings

Call us to learn more.

(701) 277-4949

Related Services

Learn More About Fargo Garage Floors & Doors

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed

Share On: